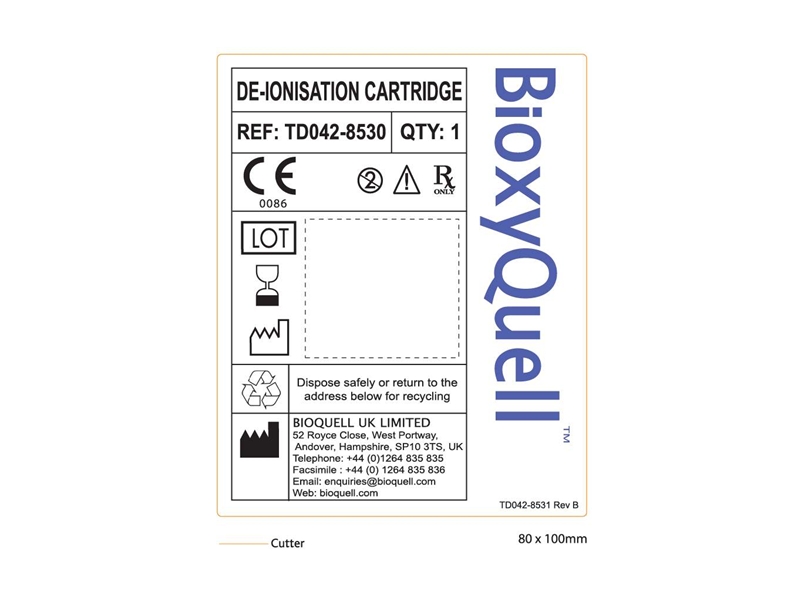

Labelservice has years of experience working with medical devise manufacturers, supplying primary and secondary labelling, plain and printed and multi part label sets, all whilst ensuring all label materials, adhesive and print adhere to the strict FDA guidelines.

Medical Device Labels FAQs

We do. We currently have both primary and secondary labelling options, available for bulk orders or your preferred volume. Our primary labels feature essential information suitable for direct attachment to medical devices.

Meanwhile, our secondary labelling includes supplementary details such as usage instructions, warnings, regulatory information and more for medical equipment. With our extensive experience and expertise in medical device labelling, we ensure all your labelling needs are conveniently met by one reliable source.

In addition to our standard medical labels, we also offer label sets and piggyback labels. Whether you require multi-part label sets for comprehensive information or piggyback labels with multiple layers of information on a single label, we have you covered.

Moreover, we offer bespoke medical device labels tailored to your requirements. So, if you require other styles, such as 2-up labels, nested labels, or any other, simply get in touch with us.

Certainly, we have the capability to print both barcodes and QR codes on our labels. These codes are essential for efficient tracking, inventory management, and regulatory compliance in the healthcare industry.

Our advanced printing technology and experienced team enable us to produce clear, accurate, and scannable barcodes and QR codes on your medical device labels. Whether for batch tracking, product authentication, or patient safety, our code printing capabilities are ready to provide you with optimal functionality for your labelling needs.

Whether you need labels for Class I, Class II, or Class III devices, we have the expertise and capabilities to provide compliant and dependable labelling solutions. Our expert team carefully prepares labels for low-risk Class I and intermediate-risk Class II devices, such as handheld surgical instruments, and X-ray systems.

Furthermore, we are equipped to produce labels for high-risk Class III devices such as pacemakers and implanted prosthetics. It’s important to note that our labels undergo rigorous testing and quality assurance processes to ensure their suitability and reliability for use with a variety of medical devices.

For your peace of mind, our labels are fully compatible with the sterilisation processes commonly employed in medical device sterilisation. We understand the critical importance of maintaining label integrity and legibility throughout sterilisation procedures.

Therefore, our labels are designed and manufactured using materials and adhesives that can withstand the rigours of sterilisation methods such as autoclaving, gamma irradiation, and ethylene oxide sterilisation. This ensures that our labels remain securely adhered to devices and retain their clarity and readability post-sterilisation.

Yes, our label materials strictly adhere to the requirements outlined in the ISO 15223-1:2021 quality system standard. We genuinely care about the quality and reliability of all our products.

Be assured that we meticulously prepare our label materials to meet the stringent standards set forth by ISO. By adhering to these standards, we guarantee our clients that our labels are of the highest quality and comply with secure applications.

Yes, our medical device labels strictly adhere to regulatory guidelines set forth by the UK’s Medicines and Healthcare Products Regulatory Agency (MHRA) and European Union regulations. We meticulously align our label materials, adhesives, and printing processes with these stringent regulations.

Our labels meet all necessary requirements for use in the medical industry within the UK. With years of experience serving medical device manufacturers, we prioritise regulatory compliance to ensure our clients have confidence in the quality and legality of our products.

Safety remains our top priority throughout our production process, and we prioritise the use of medical-grade adhesive for our medical device label stickers. Every material we utilise in our production is fully compliant with MHRA regulations.

With our extensive experience in the field, we’re adept at sourcing the most suitable materials. This ensures we deliver top-quality stickers at competitive rates, setting us apart from other companies in the market.

Certainly, we can accommodate custom label shapes and sizes to suit your specific requirements. Our flexible manufacturing processes allow us to produce labels in a wide range of shapes and sizes, tailored to fit your unique branding and labelling needs.

Whether you need labels for small, intricate devices or larger, more prominent applications, we can create bespoke solutions that meet your exact specifications. Our team is dedicated to providing you with the perfect labelling solution, ensuring that your labels not only look great but also function seamlessly in your intended application.

Our medical device labels are carefeully crafted from premium materials, including polyolefin, polypropylene, or coated paper. We select the materials, adhesives, and printing accordingly to meet the stringent requirements of the healthcare industry.

We offer a wide range of face materials, ensuring suitability for various applications and environments. Moreover, our labels are engineered to endure the demanding conditions of medical settings while adhering to stringent UKCA guidelines for safety and effectiveness.