CD / DVD Labels

Home / Full Product Range / Full Product Range / CD / DVD Labels

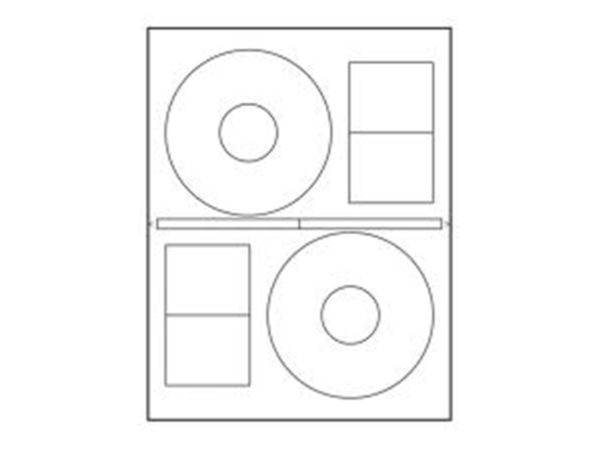

We offer from stock a range of plain or pre-printed self adhesive labels for everything from diskette faces to video spines. Many are available in multi part A4 sheets, please contact us for our stock ranges.

CD / DVD Labels FAQs

Labelservice uses a variety of materials for CD and DVD labels, with each type selected for quality and suitability for different applications. Polyester is favoured for its robustness and properties that allow it to resist heat and moisture (which is ideal for the environments CDs and DVDs are usually handled in). Vinyl is frequently used for its flexibility and general resistance to wear and tear from the outdoor environment. Polypropylene strikes a balance between performance and cost due to its blend of durability, water resistance, and more economical price point. Finally, paper labels are used for more cost-sensitive indoor projects, thanks to a good print surface and much lower costs.

Adhesive choice is vitally important to the lasting performance of CD and DVD labels. Labelservice offers a variety of adhesives suitable for this task – the first and most popular choice is permanent adhesives due to their strong bonding properties that guarantee a label remains securely fixed in most environments. For promotional materials or temporary handling, removable adhesivesare an ideal choice as they allow labels to be peeled off without leaving residue behind. For the most demanding applications and harsh conditions, high-tack adhesives provide the strongest bond.

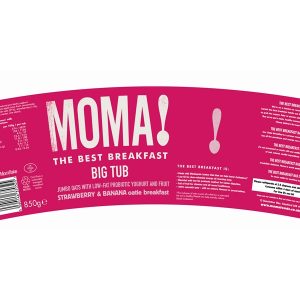

Labelservice uses advanced printing technologies that ensure high-quality and durable labels. The most predominant tech used is digital printing thanks to its versatility and ability to handle designs of all kinds and its high-resolution outputs. This is ideal for producing the most vibrant and colourful labels with fast turnaround times. The inks used are also specifically formulated for fade resistance and can withstand harsh environmental conditions without smudging or smearing. Another option to use is UV-curable inkswhich are used specifically for durability, as they cure instantly under UV light and make any images incredibly robust.

Labelservice offers various finishes that can enhance the appearance and longevity of CD and DVD labels. Gloss finishes provide a more attractive and shiny look that enhances both colour depth and vibrancy. Matte finishes are usually chosen to reduce glare, which makes labels more readable under different lighting conditions and gives a more subdued and professional appearance to the label. Laminate finishesoffer the most protection in even the most demanding environments, offering resistance against scratches, moisture, and other factors.

CD and DVD labels from Labelservice are crafted to meet precise dimensions for all applications. Standard labels will cover the main surface of a disc, and will also accommodate the central hold – this will ensure a perfect fit that also avoids interfering with the disc’s playback. It’s also possible to order custom sizes and shapes from us if you have a specific requirement, this includes full coverage designs or smaller labels that need to fit on a specific area of the disc.

Labelservice views compliance with industry standards and environmental considerations as paramount in the production of all our CD and DVD labels. We ensure that all materials and processes comply with relevant UK and EU regulations, such as REACH and RoHS, which govern the use of substances in manufacturing. We offer eco-friendly options, which include biodegradable and recyclable materials to support any client or customer’s sustainability requirements and goals.

Labelservice can incorporate various security features into CD and DVD labels that protect against counterfeiting and any unauthorised distribution. These features include holographic images, watermarks, and tamper-evident designs that can disintegrate or leave a “voiding” pattern when any removal is attempted. These features are particularly suitable for clients and customers in the entertainment, software, and professional content creation industries, where IP protection is an important consideration.

We offer from stock a range of plain or pre-printed self adhesive labels for everything from diskette faces to video spines. Many are available in multi part A4 sheets, please contact us for our stock ranges.

CD / DVD Labels FAQs

Labelservice uses a variety of materials for CD and DVD labels, with each type selected for quality and suitability for different applications. Polyester is favoured for its robustness and properties that allow it to resist heat and moisture (which is ideal for the environments CDs and DVDs are usually handled in). Vinyl is frequently used for its flexibility and general resistance to wear and tear from the outdoor environment. Polypropylene strikes a balance between performance and cost due to its blend of durability, water resistance, and more economical price point. Finally, paper labels are used for more cost-sensitive indoor projects, thanks to a good print surface and much lower costs.

Adhesive choice is vitally important to the lasting performance of CD and DVD labels. Labelservice offers a variety of adhesives suitable for this task – the first and most popular choice is permanent adhesives due to their strong bonding properties that guarantee a label remains securely fixed in most environments. For promotional materials or temporary handling, removable adhesivesare an ideal choice as they allow labels to be peeled off without leaving residue behind. For the most demanding applications and harsh conditions, high-tack adhesives provide the strongest bond.

Labelservice uses advanced printing technologies that ensure high-quality and durable labels. The most predominant tech used is digital printing thanks to its versatility and ability to handle designs of all kinds and its high-resolution outputs. This is ideal for producing the most vibrant and colourful labels with fast turnaround times. The inks used are also specifically formulated for fade resistance and can withstand harsh environmental conditions without smudging or smearing. Another option to use is UV-curable inkswhich are used specifically for durability, as they cure instantly under UV light and make any images incredibly robust.

Labelservice offers various finishes that can enhance the appearance and longevity of CD and DVD labels. Gloss finishes provide a more attractive and shiny look that enhances both colour depth and vibrancy. Matte finishes are usually chosen to reduce glare, which makes labels more readable under different lighting conditions and gives a more subdued and professional appearance to the label. Laminate finishesoffer the most protection in even the most demanding environments, offering resistance against scratches, moisture, and other factors.

CD and DVD labels from Labelservice are crafted to meet precise dimensions for all applications. Standard labels will cover the main surface of a disc, and will also accommodate the central hold – this will ensure a perfect fit that also avoids interfering with the disc’s playback. It’s also possible to order custom sizes and shapes from us if you have a specific requirement, this includes full coverage designs or smaller labels that need to fit on a specific area of the disc.

Labelservice views compliance with industry standards and environmental considerations as paramount in the production of all our CD and DVD labels. We ensure that all materials and processes comply with relevant UK and EU regulations, such as REACH and RoHS, which govern the use of substances in manufacturing. We offer eco-friendly options, which include biodegradable and recyclable materials to support any client or customer’s sustainability requirements and goals.

Labelservice can incorporate various security features into CD and DVD labels that protect against counterfeiting and any unauthorised distribution. These features include holographic images, watermarks, and tamper-evident designs that can disintegrate or leave a “voiding” pattern when any removal is attempted. These features are particularly suitable for clients and customers in the entertainment, software, and professional content creation industries, where IP protection is an important consideration.