Digital Direct Thermal labels

Home / Full Product Range / Digital Labels / Digital Direct Thermal labels

Direct Thermal Labels FAQs

A direct thermal label is a type of label that’s been manufactured using the direct thermal printing process. In this method, heat is applied directly to a specially treated label material that contains ink embedded within it. When the print head of the direct thermal printer comes into contact with the label, the heat causes a reaction in the ink, resulting in the appearance of the printed text or imagery. As the label cools down, the printed content becomes clearly visible.

One of the primary advantages of direct thermal labels is that they do not require any ink, toner, or ribbon to produce an image. Instead, they rely solely on heat-sensitive materials. This makes them a cost-effective solution for various applications. However, it’s worth noting that direct thermal labels are typically ideal for applications requiring only a short shelf life.

Thermal labels refer to a broad category of labels that are printed using heat. The heat is applied to a specific type of paper or material, resulting in the production of an image. Within the realm of thermal labels, there are two primary methods of printing: direct thermal and thermal transfer.

Direct Thermal Labels:

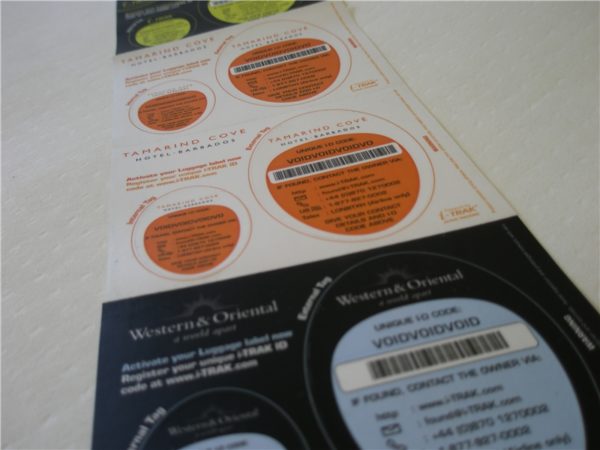

Direct thermal printing utilises chemically treated, heat-sensitive media. As this media is passed under a thermal printhead, it undergoes a reaction and blackens, producing the desired image or text. This method is particularly suitable for short-term applications, typically lasting less than six months. One of the notable characteristics of direct thermal labels is their sensitivity to external factors such as light and heat. Over time, exposure to these elements might cause the labels to darken. These labels are commonly employed in applications like shipping labels, receipts, and other scenarios where the longevity of the label isn’t a primary concern.

Thermal Transfer Labels:

Thermal transfer printing stands out due to its use of a heated ribbon to imprint images on a wide array of materials. The heat from the printhead causes the ink from the ribbon to be released and subsequently attach to the label surface. This ensures the production of a more durable and long-lasting image. Given its resilience, thermal transfer is the go-to method for long-term applications, especially those spanning more than six months or in situations where the label will be subjected to harsh conditions. The resulting labels are notably resistant to challenges such as UV light, heat, and moisture, making them an ideal choice for outdoor use or environments that pose a challenge to label integrity.

Food Service: Direct thermal labels are often used for food packaging, especially for items with a short shelf life. They can be used to display information such as ingredients, expiration dates, and barcodes.

Retail: In the retail sector, these labels are used for price tags, shelf labelling, and product identification.

Pharmaceuticals: Direct thermal labels can be found on medicine bottles and packaging, providing essential information about the drug, its dosage, and expiration date.

Shipping: They are a popular choice for shipping labels due to their ability to produce clear barcodes and addresses. This ensures efficient handling and delivery of packages.

Barcodes and Scannable Material: Direct thermal printing is frequently chosen for barcodes and other scannable materials because of its ability to produce sharp, high-definition graphics and text.

Event Tickets and Coupons: The labels are also used for event tickets and promotional coupons, offering clarity and durability for short-term use.

Direct thermal printing is a cost-effective method that eliminates the need for ink or ribbons, relying solely on chemically treated material. It consistently delivers sharp images, making it ideal for barcodes and scannable materials. Environmentally conscious businesses appreciate its reduced waste output, and its user-friendly nature ensures minimal errors during printing. While perfect for short-term applications like shipping labels, its sensitivity to external factors might limit its use in long-term scenarios.

Direct thermal labels are primarily made from heat-sensitive paper or synthetic materials that react to produce an image when exposed to a thermal printhead. The adhesives used can vary, with the most common being permanent for general applications, all-temperature for extreme conditions, aggressive for a stronger bond, and removable for labels that need to be easily taken off without leaving residue.

Direct Thermal Labels FAQs

A direct thermal label is a type of label that’s been manufactured using the direct thermal printing process. In this method, heat is applied directly to a specially treated label material that contains ink embedded within it. When the print head of the direct thermal printer comes into contact with the label, the heat causes a reaction in the ink, resulting in the appearance of the printed text or imagery. As the label cools down, the printed content becomes clearly visible.

One of the primary advantages of direct thermal labels is that they do not require any ink, toner, or ribbon to produce an image. Instead, they rely solely on heat-sensitive materials. This makes them a cost-effective solution for various applications. However, it’s worth noting that direct thermal labels are typically ideal for applications requiring only a short shelf life.

Thermal labels refer to a broad category of labels that are printed using heat. The heat is applied to a specific type of paper or material, resulting in the production of an image. Within the realm of thermal labels, there are two primary methods of printing: direct thermal and thermal transfer.

Direct Thermal Labels:

Direct thermal printing utilises chemically treated, heat-sensitive media. As this media is passed under a thermal printhead, it undergoes a reaction and blackens, producing the desired image or text. This method is particularly suitable for short-term applications, typically lasting less than six months. One of the notable characteristics of direct thermal labels is their sensitivity to external factors such as light and heat. Over time, exposure to these elements might cause the labels to darken. These labels are commonly employed in applications like shipping labels, receipts, and other scenarios where the longevity of the label isn’t a primary concern.

Thermal Transfer Labels:

Thermal transfer printing stands out due to its use of a heated ribbon to imprint images on a wide array of materials. The heat from the printhead causes the ink from the ribbon to be released and subsequently attach to the label surface. This ensures the production of a more durable and long-lasting image. Given its resilience, thermal transfer is the go-to method for long-term applications, especially those spanning more than six months or in situations where the label will be subjected to harsh conditions. The resulting labels are notably resistant to challenges such as UV light, heat, and moisture, making them an ideal choice for outdoor use or environments that pose a challenge to label integrity.

Food Service: Direct thermal labels are often used for food packaging, especially for items with a short shelf life. They can be used to display information such as ingredients, expiration dates, and barcodes.

Retail: In the retail sector, these labels are used for price tags, shelf labelling, and product identification.

Pharmaceuticals: Direct thermal labels can be found on medicine bottles and packaging, providing essential information about the drug, its dosage, and expiration date.

Shipping: They are a popular choice for shipping labels due to their ability to produce clear barcodes and addresses. This ensures efficient handling and delivery of packages.

Barcodes and Scannable Material: Direct thermal printing is frequently chosen for barcodes and other scannable materials because of its ability to produce sharp, high-definition graphics and text.

Event Tickets and Coupons: The labels are also used for event tickets and promotional coupons, offering clarity and durability for short-term use.

Direct thermal printing is a cost-effective method that eliminates the need for ink or ribbons, relying solely on chemically treated material. It consistently delivers sharp images, making it ideal for barcodes and scannable materials. Environmentally conscious businesses appreciate its reduced waste output, and its user-friendly nature ensures minimal errors during printing. While perfect for short-term applications like shipping labels, its sensitivity to external factors might limit its use in long-term scenarios.

Direct thermal labels are primarily made from heat-sensitive paper or synthetic materials that react to produce an image when exposed to a thermal printhead. The adhesives used can vary, with the most common being permanent for general applications, all-temperature for extreme conditions, aggressive for a stronger bond, and removable for labels that need to be easily taken off without leaving residue.