Drum and IBC Labels

Home / Full Product Range / Chemical Labels / Drum and IBC Labels

Labelservice supplies all types of self adhesive chemical labels for plastic and steel drums and IBC’s. Our materials are fully BS5608 approved and suitable for subsequent overprinting by Thermal Transfer, laser or inkjet printing.

Drum & IBC Labels FAQs

Drums and barrels are cylindrical containers predominantly used in international shipping for the storage and transportation of liquids and other materials. The terms are often used interchangeably, but there can be nuances in their capacities or intended uses. They are commonly used in industries such as oil, chemicals, and food processing. Typically, a drum measures about 2 feet in diameter and 3 feet tall, with the standard size being 55 gallons (about 208 litres). And can be made from steel, plastic, or fibre depending on their intended use.

Intermediate Bulk Containers (IBCs) are larger, industrial-grade containers tailored for the mass handling, transport, and storage of liquids, semi-solids, pastes, or solids. Offering a more efficient solution for transporting bulk quantities, IBCs are designed to store and transport liquids as specified in international regulations, such as the Code of Federal Regulations and the United Nations’ Recommendations on the Transport of Dangerous Goods. This encompasses a range of materials, from combustible and flammable to non-hazardous liquids. IBCs can hold between 450 up to 3,000 L (119 to 793 gallons) and are constructed mainly from steel or plastic.

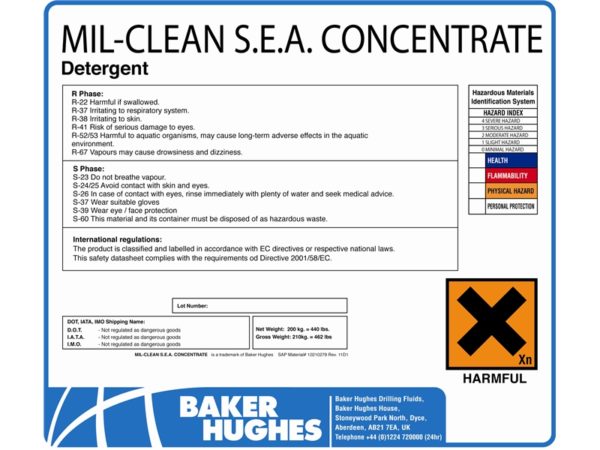

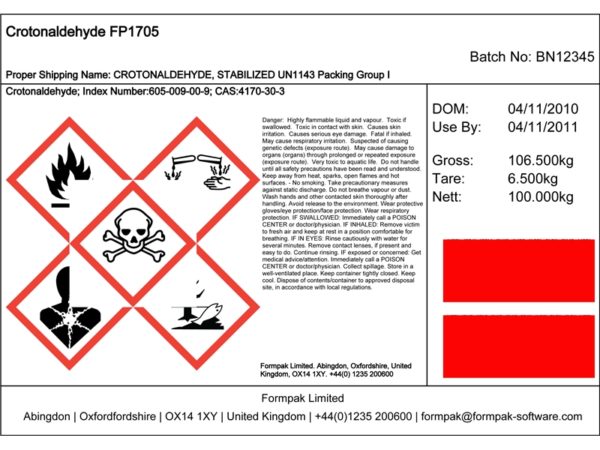

In International shipping and industrial contexts, drums require specific labelling to ensure safety, compliance and proper handling. Here’s an overview of the types of labels commonly used on barrel drums:

Content Identification: Labels that specify the contents of the drum, whether it’s a particular chemical, petroleum product, pharmaceutical, or any other substance. This helps handlers and receivers identify the contents quickly.

Hazard Communication: For drums containing hazardous materials, labels indicating the nature of the hazard are crucial. This can include symbols and text indicating if the contents are flammable, explosive, corrosive, or toxic.

Regulatory Compliance: Depending on the contents and the countries of export and import, there might be specific regulatory labels required. For instance, drums storing hazardous materials might need to comply with EPA, OSHA, GHS, and the DOT regulations.

Handling Instructions: These labels provide information on how the drum should be handled, stored, and transported. It can include instructions like “Keep Upright” or “Handle with Care.”

Barcode Labels: These labels facilitate tracking and inventory management. They can be scanned to retrieve information about the drum’s contents, origin, destination, and other relevant data.

Durability Indicators: Given that drums are often exposed to various environmental conditions, some labels are made of durable materials like vinyl or polyester, ensuring they remain legible and intact.

Waste and Recycling Indicators: For drums used to store waste or materials meant for recycling, labels indicating “Non-Hazardous Waste,” “Recovered Materials,” or “Materials for Recycle” can be used.

Manufacturer and Batch Information: Labels indicating the manufacturer of the contents, batch number, production date, and expiry date, if applicable.

Internationally, the labelling of drums and IBCs (Intermediate Bulk Containers), especially when they contain hazardous materials, is regulated by several organisations and conventions. Here’s an overview:

United Nations Economic Commission for Europe (UNECE): The UNECE provides the Recommendations on the Transport of Dangerous Goods, which are widely adopted and serve as the basis for many national and international regulations. These recommendations cover the requirements for packaging, labelling, and transporting dangerous goods, including those stored in drums and IBCs.

International Air Transport Association (IATA): For goods transported by air, IATA’s Dangerous Goods Regulations provide guidelines on the labelling and packaging of hazardous materials.

International Maritime Organisation (IMO): For sea transport, the IMO’s International Maritime Dangerous Goods (IMDG) Code provides guidelines for the safe transport of dangerous goods by sea, including labelling requirements.

Institute of Plastic Drums: While not a regulatory body, the Institute of Plastic Drums provides guidelines on labelling for plastic drums and composite IBCs, which can be useful for manufacturers and shippers.

DOT Regulations: This organisation emphasises the importance of keeping labels intact on empty IBCs shipped for reconditioning. The labels that identify the material last contained are crucial for safety during transportation and at the reconditioning workplace. The requirement for product labels on empty IBCs is based on the DOT Regulation 49 CFR 172.302 (d).

The Globally Harmonised System of Classification and Labelling of Chemicals (GHS) has introduced significant changes to the way hazardous chemicals are labelled, and this directly affects drum shipping labels. Here’s how GHS requirements impact drum shipping labels:

Standardised Pictograms: GHS introduced a set of standard pictograms that convey specific hazards associated with chemicals. These pictograms are universally understood symbols that ensure that even if a person cannot read the language of the label, they can still understand the hazards associated with the chemical.

Signal Words: GHS labels use specific signal words, either “Danger” or “Warning”, to indicate the severity of the hazard. “Danger” is used for more severe hazards, while “Warning” is used for less severe hazards.

Hazard and Precautionary Statements: GHS labels include hazard statements that describe the nature and degree of the hazard. Additionally, precautionary statements provide guidance on how to avoid adverse effects.

Product Identifier: This is the name or number used for a hazardous product on a label or in the Safety Data Sheet (SDS). It ensures that the exact chemical or mixture can be accurately identified.

Supplier Information: The label must include the name, address, and telephone number of the manufacturer or supplier of the product.

Effective Dates: All hazardous chemicals shipped after June 1, 2015, must be labelled with the specified GHS elements. However, manufacturers and distributors had the option to adopt the new labelling system before this effective date.

Consistency Across Borders: Since GHS is a global system, it ensures that drums and other containers are labelled consistently no matter where they are manufactured or shipped. This is particularly beneficial for international trade.

GS1 standards are a set of global standards for business communication, primarily focusing on the identification of products, shipments, and services. They are developed and maintained by GS1, an international non-profit organisation.

Regarding the use of GS1 standards on drums shipped internationally, while GS1 provides guidelines for shipping and receiving, including the labelling of logistics units, it’s not explicitly mandatory for all drums or IBCs shipped internationally. However, many businesses and countries adopt these standards to ensure consistency, traceability, and efficiency in international trade.

Labelservice supplies all types of self adhesive chemical labels for plastic and steel drums and IBC’s. Our materials are fully BS5608 approved and suitable for subsequent overprinting by Thermal Transfer, laser or inkjet printing.

Drum & IBC Labels FAQs

Drums and barrels are cylindrical containers predominantly used in international shipping for the storage and transportation of liquids and other materials. The terms are often used interchangeably, but there can be nuances in their capacities or intended uses. They are commonly used in industries such as oil, chemicals, and food processing. Typically, a drum measures about 2 feet in diameter and 3 feet tall, with the standard size being 55 gallons (about 208 litres). And can be made from steel, plastic, or fibre depending on their intended use.

Intermediate Bulk Containers (IBCs) are larger, industrial-grade containers tailored for the mass handling, transport, and storage of liquids, semi-solids, pastes, or solids. Offering a more efficient solution for transporting bulk quantities, IBCs are designed to store and transport liquids as specified in international regulations, such as the Code of Federal Regulations and the United Nations’ Recommendations on the Transport of Dangerous Goods. This encompasses a range of materials, from combustible and flammable to non-hazardous liquids. IBCs can hold between 450 up to 3,000 L (119 to 793 gallons) and are constructed mainly from steel or plastic.

In International shipping and industrial contexts, drums require specific labelling to ensure safety, compliance and proper handling. Here’s an overview of the types of labels commonly used on barrel drums:

Content Identification: Labels that specify the contents of the drum, whether it’s a particular chemical, petroleum product, pharmaceutical, or any other substance. This helps handlers and receivers identify the contents quickly.

Hazard Communication: For drums containing hazardous materials, labels indicating the nature of the hazard are crucial. This can include symbols and text indicating if the contents are flammable, explosive, corrosive, or toxic.

Regulatory Compliance: Depending on the contents and the countries of export and import, there might be specific regulatory labels required. For instance, drums storing hazardous materials might need to comply with EPA, OSHA, GHS, and the DOT regulations.

Handling Instructions: These labels provide information on how the drum should be handled, stored, and transported. It can include instructions like “Keep Upright” or “Handle with Care.”

Barcode Labels: These labels facilitate tracking and inventory management. They can be scanned to retrieve information about the drum’s contents, origin, destination, and other relevant data.

Durability Indicators: Given that drums are often exposed to various environmental conditions, some labels are made of durable materials like vinyl or polyester, ensuring they remain legible and intact.

Waste and Recycling Indicators: For drums used to store waste or materials meant for recycling, labels indicating “Non-Hazardous Waste,” “Recovered Materials,” or “Materials for Recycle” can be used.

Manufacturer and Batch Information: Labels indicating the manufacturer of the contents, batch number, production date, and expiry date, if applicable.

Internationally, the labelling of drums and IBCs (Intermediate Bulk Containers), especially when they contain hazardous materials, is regulated by several organisations and conventions. Here’s an overview:

United Nations Economic Commission for Europe (UNECE): The UNECE provides the Recommendations on the Transport of Dangerous Goods, which are widely adopted and serve as the basis for many national and international regulations. These recommendations cover the requirements for packaging, labelling, and transporting dangerous goods, including those stored in drums and IBCs.

International Air Transport Association (IATA): For goods transported by air, IATA’s Dangerous Goods Regulations provide guidelines on the labelling and packaging of hazardous materials.

International Maritime Organisation (IMO): For sea transport, the IMO’s International Maritime Dangerous Goods (IMDG) Code provides guidelines for the safe transport of dangerous goods by sea, including labelling requirements.

Institute of Plastic Drums: While not a regulatory body, the Institute of Plastic Drums provides guidelines on labelling for plastic drums and composite IBCs, which can be useful for manufacturers and shippers.

DOT Regulations: This organisation emphasises the importance of keeping labels intact on empty IBCs shipped for reconditioning. The labels that identify the material last contained are crucial for safety during transportation and at the reconditioning workplace. The requirement for product labels on empty IBCs is based on the DOT Regulation 49 CFR 172.302 (d).

The Globally Harmonised System of Classification and Labelling of Chemicals (GHS) has introduced significant changes to the way hazardous chemicals are labelled, and this directly affects drum shipping labels. Here’s how GHS requirements impact drum shipping labels:

Standardised Pictograms: GHS introduced a set of standard pictograms that convey specific hazards associated with chemicals. These pictograms are universally understood symbols that ensure that even if a person cannot read the language of the label, they can still understand the hazards associated with the chemical.

Signal Words: GHS labels use specific signal words, either “Danger” or “Warning”, to indicate the severity of the hazard. “Danger” is used for more severe hazards, while “Warning” is used for less severe hazards.

Hazard and Precautionary Statements: GHS labels include hazard statements that describe the nature and degree of the hazard. Additionally, precautionary statements provide guidance on how to avoid adverse effects.

Product Identifier: This is the name or number used for a hazardous product on a label or in the Safety Data Sheet (SDS). It ensures that the exact chemical or mixture can be accurately identified.

Supplier Information: The label must include the name, address, and telephone number of the manufacturer or supplier of the product.

Effective Dates: All hazardous chemicals shipped after June 1, 2015, must be labelled with the specified GHS elements. However, manufacturers and distributors had the option to adopt the new labelling system before this effective date.

Consistency Across Borders: Since GHS is a global system, it ensures that drums and other containers are labelled consistently no matter where they are manufactured or shipped. This is particularly beneficial for international trade.

GS1 standards are a set of global standards for business communication, primarily focusing on the identification of products, shipments, and services. They are developed and maintained by GS1, an international non-profit organisation.

Regarding the use of GS1 standards on drums shipped internationally, while GS1 provides guidelines for shipping and receiving, including the labelling of logistics units, it’s not explicitly mandatory for all drums or IBCs shipped internationally. However, many businesses and countries adopt these standards to ensure consistency, traceability, and efficiency in international trade.