Lubricant Labels

Home / Full Product Range / Chemical Labels / Lubricant Labels

Printed bespoke to your requirements, lubricant labels can be printed on a range of face papers and adhesives. Please contact us for free samples or a printed proof from your artwork.

Lubricants and Grease Labels FAQs

Lubricants and greases are vital in reducing friction between moving parts, safeguarding against wear, and prolonging the life of machinery. Lubricants are substances introduced to diminish friction and wear between two moving surfaces. They can manifest in various forms, from liquid to semi-solid to solid. Traditionally, lubricants are derived from crude oil through refining processes, known as mineral lubricants. However, there are also synthetic lubricants, which are chemically engineered to possess specific properties, often outperforming their mineral counterparts, especially under extreme conditions. Another category is bio-based lubricants, which are sourced from renewable resources. These are not only biodegradable but also environmentally friendly. Common applications for lubricants span engines, transmissions, hydraulics, turbines, compressors, and numerous other industrial uses. Key properties to consider when evaluating lubricants include viscosity, pour point, flash point, and oxidation stability.

Grease is a semi-solid lubricant comprising a base oil, a thickener, and various additives. The role of the thickener is akin to a sponge; it retains the base oil and releases it when under pressure. There are several types of greases. Soap-based greases utilise common soaps like lithium, calcium, sodium, and aluminium as thickeners. In contrast, non-soap greases might incorporate thickeners such as bentone, silica, or polyurea. Additionally, there are synthetic greases that employ synthetic oils as the base. Grease is typically applied to bearings, joints, linkages, and other areas where a liquid lubricant might not remain in place. When assessing grease, properties like dropping point, workability, water resistance, and oxidation stability are crucial.

There are also specialised lubricants and greases tailored for specific needs. For instance, high-temperature greases are formulated for applications exposed to intense heat, while low-temperature greases are ideal for cold environments. In the food processing industry, food-grade lubricants are used, which are safe for incidental food contact. There are also extreme pressure lubricants containing additives that, under high pressure, react to form a protective layer on metal surfaces. Another category is water-resistant lubricants, designed to maintain their efficacy even in the presence of water.

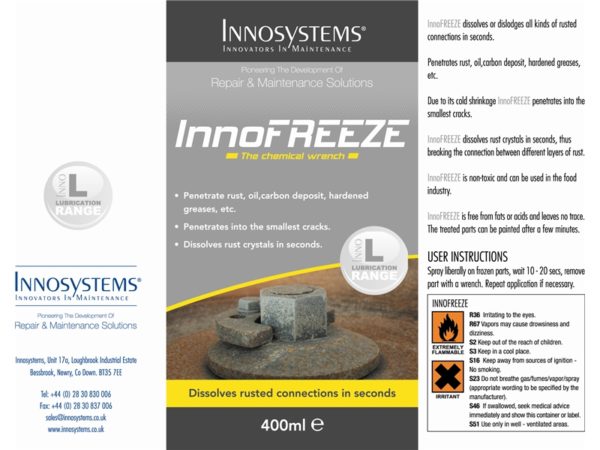

In the UK, the labelling of chemical products, including greases and lubricants, is primarily governed by the Classification, Labelling and Packaging (CLP) Regulation. This regulation requires manufacturers, importers, and distributors to classify, label, and package hazardous chemicals appropriately before placing them on the market.

The labels must include specific information such as:

Product Identifier: The commercial name or designation of the product.

Supplier Identification: Name, address, and contact details of the manufacturer or distributor.

Hazard Pictograms: Symbols that provide a visual representation of the hazards associated with the product.

Signal Words: Words such as “Danger” or “Warning” that indicate the level of hazard.

Hazard Statements: Descriptions of the nature and degree of the hazards, e.g., “Causes skin irritation” or “Flammable liquid and vapor.”

The following information is recommended but not mandatory:

Precautionary Statements: Instructions on how to prevent exposure and reduce the risk, covering prevention, response, storage, and disposal.

First Aid Measures: Instructions on what to do in case of accidental exposure, ingestion, inhalation, or contact.

Storage Instructions: Guidelines on how to store the product safely, including temperature range and conditions to avoid.

Disposal Instructions: Information on how to dispose of the product and its container safely.

Handling Precautions: Recommendations on safe handling practices, including the use of personal protective equipment (PPE) like gloves or goggles.

Physical and Chemical Properties: Information such as appearance, odour, pH, boiling point, and flash point.

Stability and Reactivity: Information on the product’s stability and any materials or conditions to avoid due to potential reactions.

Toxicological Information: Details on the health effects of exposure, including symptoms and required treatments.

Environmental Information: Any potential environmental hazards, such as toxicity to aquatic life.

Regulatory Information: Details on any specific regulations that apply to the product in the region where it’s sold.

Other Information: Any other relevant safety information or references to more detailed safety data sheets (SDS).

Additionally, for products like greases and lubricants, there might be specific industry standards or guidelines that dictate additional labelling requirements, such as technical specifications or application instructions.

If you need detailed information or specific regulations related to grease and lubricant product labelling in the UK, it might be best to consult the Health and Safety Executive (HSE)

The average shelf life of grease and lubricants can vary based on their composition and intended use. However, many general-purpose greases and lubricants have a shelf life ranging from 1 to 5 years when stored under proper conditions. While not always a legal requirement, many manufacturers display the shelf life of grease and lubricants on their labels.

Printed bespoke to your requirements, lubricant labels can be printed on a range of face papers and adhesives. Please contact us for free samples or a printed proof from your artwork.

Lubricants and Grease Labels FAQs

Lubricants and greases are vital in reducing friction between moving parts, safeguarding against wear, and prolonging the life of machinery. Lubricants are substances introduced to diminish friction and wear between two moving surfaces. They can manifest in various forms, from liquid to semi-solid to solid. Traditionally, lubricants are derived from crude oil through refining processes, known as mineral lubricants. However, there are also synthetic lubricants, which are chemically engineered to possess specific properties, often outperforming their mineral counterparts, especially under extreme conditions. Another category is bio-based lubricants, which are sourced from renewable resources. These are not only biodegradable but also environmentally friendly. Common applications for lubricants span engines, transmissions, hydraulics, turbines, compressors, and numerous other industrial uses. Key properties to consider when evaluating lubricants include viscosity, pour point, flash point, and oxidation stability.

Grease is a semi-solid lubricant comprising a base oil, a thickener, and various additives. The role of the thickener is akin to a sponge; it retains the base oil and releases it when under pressure. There are several types of greases. Soap-based greases utilise common soaps like lithium, calcium, sodium, and aluminium as thickeners. In contrast, non-soap greases might incorporate thickeners such as bentone, silica, or polyurea. Additionally, there are synthetic greases that employ synthetic oils as the base. Grease is typically applied to bearings, joints, linkages, and other areas where a liquid lubricant might not remain in place. When assessing grease, properties like dropping point, workability, water resistance, and oxidation stability are crucial.

There are also specialised lubricants and greases tailored for specific needs. For instance, high-temperature greases are formulated for applications exposed to intense heat, while low-temperature greases are ideal for cold environments. In the food processing industry, food-grade lubricants are used, which are safe for incidental food contact. There are also extreme pressure lubricants containing additives that, under high pressure, react to form a protective layer on metal surfaces. Another category is water-resistant lubricants, designed to maintain their efficacy even in the presence of water.

In the UK, the labelling of chemical products, including greases and lubricants, is primarily governed by the Classification, Labelling and Packaging (CLP) Regulation. This regulation requires manufacturers, importers, and distributors to classify, label, and package hazardous chemicals appropriately before placing them on the market.

The labels must include specific information such as:

Product Identifier: The commercial name or designation of the product.

Supplier Identification: Name, address, and contact details of the manufacturer or distributor.

Hazard Pictograms: Symbols that provide a visual representation of the hazards associated with the product.

Signal Words: Words such as “Danger” or “Warning” that indicate the level of hazard.

Hazard Statements: Descriptions of the nature and degree of the hazards, e.g., “Causes skin irritation” or “Flammable liquid and vapor.”

The following information is recommended but not mandatory:

Precautionary Statements: Instructions on how to prevent exposure and reduce the risk, covering prevention, response, storage, and disposal.

First Aid Measures: Instructions on what to do in case of accidental exposure, ingestion, inhalation, or contact.

Storage Instructions: Guidelines on how to store the product safely, including temperature range and conditions to avoid.

Disposal Instructions: Information on how to dispose of the product and its container safely.

Handling Precautions: Recommendations on safe handling practices, including the use of personal protective equipment (PPE) like gloves or goggles.

Physical and Chemical Properties: Information such as appearance, odour, pH, boiling point, and flash point.

Stability and Reactivity: Information on the product’s stability and any materials or conditions to avoid due to potential reactions.

Toxicological Information: Details on the health effects of exposure, including symptoms and required treatments.

Environmental Information: Any potential environmental hazards, such as toxicity to aquatic life.

Regulatory Information: Details on any specific regulations that apply to the product in the region where it’s sold.

Other Information: Any other relevant safety information or references to more detailed safety data sheets (SDS).

Additionally, for products like greases and lubricants, there might be specific industry standards or guidelines that dictate additional labelling requirements, such as technical specifications or application instructions.

If you need detailed information or specific regulations related to grease and lubricant product labelling in the UK, it might be best to consult the Health and Safety Executive (HSE)

The average shelf life of grease and lubricants can vary based on their composition and intended use. However, many general-purpose greases and lubricants have a shelf life ranging from 1 to 5 years when stored under proper conditions. While not always a legal requirement, many manufacturers display the shelf life of grease and lubricants on their labels.