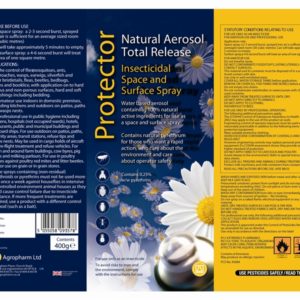

Automotive Labels

Home / Full Product Range / Chemical Labels / Automotive Labels

Printed bespoke to your requirements, automotive labels can be printed on a range of face papers and adhesives. Please contact us for free samples or a printed proof from your artwork.

Automotive Label FAQs

Labels on adhesive and sealant products play a pivotal role in ensuring user safety and product efficacy. They provide crucial information about the product’s composition, application methods, and potential hazards. Without these labels, consumers might misuse the product, leading to ineffective bonding or, worse, potential health risks. Additionally, labels help in distinguishing between various types of adhesives and sealants, ensuring that users select the right product for their specific needs.

Every adhesive and sealant product must have a label that effectively communicates vital information. Here are the essential components that should be present on such labels:

Product Identification:

Product Name and Brand: Clearly state the name of the adhesive or sealant. This helps users quickly identify the product and ensures they are using the correct type for their needs.

Batch Number or Code: This is crucial for quality control and traceability. If there’s a recall or an issue with a particular batch, users can quickly determine if their product is affected.

Hazard Pictograms:These are symbols that visually represent potential risks associated with the product. Common pictograms might indicate if a product is flammable, toxic, or corrosive. They serve as immediate visual warnings to users.

Safety Information:First-Aid Measures: Instructions on what to do if someone comes into contact with the product, ingests it, or inhales its fumes. This can be lifesaving information in emergencies.

Precautionary Statements: These are recommendations on how to handle, store, and dispose of the product safely. They might include warnings like “Keep out of reach of children” or “Use in a well-ventilated area.”

Storage and Disposal Instructions: Guidelines on how to store the product to maintain its efficacy and shelf life, and how to dispose of it safely and environmentally responsibly.

Usage Instructions:

Application Methods: Detailed steps on how to apply the adhesive or sealant, including surface preparation, recommended tools, and curing times.

Surface Preparation Guidelines: Instructions on how to prepare surfaces before applying the product to ensure optimal adhesion.

Drying or Curing Time: Information on how long it takes for the adhesive or sealant to set or cure completely. This helps users know when it’s safe to move or load the bonded items.

Technical Information:

Product’s Chemical Composition: A list of the main ingredients or chemicals in the product. This is especially important for users who might be allergic to certain compounds or for those who are looking for specific adhesive properties.

Performance Specifications: Data on the product’s capabilities, such as bond strength, temperature resistance, and flexibility. This helps users determine if the product is suitable for their specific application.

For adhesive and sealant products that are shipped by sea, especially those deemed hazardous, it’s crucial to ensure that their labels are BS5609 compliant. This ensures that in the event of any mishaps at sea, the product’s information remains accessible and legible, aiding in the proper handling and disposal of the product.

REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) is a European Union regulation that addresses the production and use of chemical substances and their potential impacts on both human health and the environment. One of the key aspects of REACH is the requirement for labelling of certain substances to ensure that users are informed about their properties and any associated hazards.

Information Requirement: Adhesive and sealant products that contain substances classified under REACH must have labels that provide clear information about the hazards. This ensures that users are aware of the risks and can take appropriate precautions.

Consistency: REACH labelling requirements ensure consistency across products, making it easier for users to understand and compare products.

Safety: By providing clear hazard information, REACH labelling helps reduce the risk of accidents and health issues related to the use of adhesives and sealants.

Regulatory Compliance: Manufacturers and suppliers of adhesive and sealant products must ensure that their labels comply with REACH regulations. Non-compliance can result in penalties and restrictions on the sale of products.

The Diisocyanate Regulations in the UK pertain to the safe use and handling of diisocyanates, which are chemicals commonly used in the production of polyurethane (PU) products, including adhesives and sealants. Here’s a summary of the regulations based on the provided search results:

The EU REACH Regulation, which addresses the safe use of chemicals, was incorporated into UK law on 1 January 2021, known as UK REACH. The restriction on diisocyanates (EU 2020/1149) was also carried into UK legislation, with subsequent modifications made by SI 2021 No. 904 Part 2.

Labelling Requirements: Effective from 24th February 2022, products sold within the UK containing a total monomeric diisocyanate concentration greater than 0.1% and intended for professional or industrial use must have the following statement on the product label: “As of 24th August 2023, adequate training is required before industrial or professional use.”

The Impact of 2023 Isocyanate Regulations on adhesive products

In 2023, the UK will see the implementation of new isocyanate regulations that will significantly influence the adhesive industry, particularly concerning the labelling of adhesive products. Here’s a concise overview of the implications of these regulations on product labelling:

Background:

Isocyanates, commonly found in polyurethane adhesives, are chemicals known for their reactivity. They have been identified as potential respiratory and skin sensitizers, leading to concerns about health risks associated with their exposure.

Labelling Requirements:

Presence Indication: All adhesive products containing diisocyanates will be mandated to have clear labels indicating the presence of these chemicals. This ensures users are informed and can take necessary precautions.

Safety Information: Labels will need to provide safety information, including potential risks associated with exposure and guidance on safe handling, storage, and disposal.

Training Information: Given the requirement for adequate training before using these products, labels might also need to indicate the necessity for such training or provide references to where users can access this training.

Printed bespoke to your requirements, automotive labels can be printed on a range of face papers and adhesives. Please contact us for free samples or a printed proof from your artwork.

Automotive Label FAQs

Labels on adhesive and sealant products play a pivotal role in ensuring user safety and product efficacy. They provide crucial information about the product’s composition, application methods, and potential hazards. Without these labels, consumers might misuse the product, leading to ineffective bonding or, worse, potential health risks. Additionally, labels help in distinguishing between various types of adhesives and sealants, ensuring that users select the right product for their specific needs.

Every adhesive and sealant product must have a label that effectively communicates vital information. Here are the essential components that should be present on such labels:

Product Identification:

Product Name and Brand: Clearly state the name of the adhesive or sealant. This helps users quickly identify the product and ensures they are using the correct type for their needs.

Batch Number or Code: This is crucial for quality control and traceability. If there’s a recall or an issue with a particular batch, users can quickly determine if their product is affected.

Hazard Pictograms:These are symbols that visually represent potential risks associated with the product. Common pictograms might indicate if a product is flammable, toxic, or corrosive. They serve as immediate visual warnings to users.

Safety Information:First-Aid Measures: Instructions on what to do if someone comes into contact with the product, ingests it, or inhales its fumes. This can be lifesaving information in emergencies.

Precautionary Statements: These are recommendations on how to handle, store, and dispose of the product safely. They might include warnings like “Keep out of reach of children” or “Use in a well-ventilated area.”

Storage and Disposal Instructions: Guidelines on how to store the product to maintain its efficacy and shelf life, and how to dispose of it safely and environmentally responsibly.

Usage Instructions:

Application Methods: Detailed steps on how to apply the adhesive or sealant, including surface preparation, recommended tools, and curing times.

Surface Preparation Guidelines: Instructions on how to prepare surfaces before applying the product to ensure optimal adhesion.

Drying or Curing Time: Information on how long it takes for the adhesive or sealant to set or cure completely. This helps users know when it’s safe to move or load the bonded items.

Technical Information:

Product’s Chemical Composition: A list of the main ingredients or chemicals in the product. This is especially important for users who might be allergic to certain compounds or for those who are looking for specific adhesive properties.

Performance Specifications: Data on the product’s capabilities, such as bond strength, temperature resistance, and flexibility. This helps users determine if the product is suitable for their specific application.

For adhesive and sealant products that are shipped by sea, especially those deemed hazardous, it’s crucial to ensure that their labels are BS5609 compliant. This ensures that in the event of any mishaps at sea, the product’s information remains accessible and legible, aiding in the proper handling and disposal of the product.

REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) is a European Union regulation that addresses the production and use of chemical substances and their potential impacts on both human health and the environment. One of the key aspects of REACH is the requirement for labelling of certain substances to ensure that users are informed about their properties and any associated hazards.

Information Requirement: Adhesive and sealant products that contain substances classified under REACH must have labels that provide clear information about the hazards. This ensures that users are aware of the risks and can take appropriate precautions.

Consistency: REACH labelling requirements ensure consistency across products, making it easier for users to understand and compare products.

Safety: By providing clear hazard information, REACH labelling helps reduce the risk of accidents and health issues related to the use of adhesives and sealants.

Regulatory Compliance: Manufacturers and suppliers of adhesive and sealant products must ensure that their labels comply with REACH regulations. Non-compliance can result in penalties and restrictions on the sale of products.

The Diisocyanate Regulations in the UK pertain to the safe use and handling of diisocyanates, which are chemicals commonly used in the production of polyurethane (PU) products, including adhesives and sealants. Here’s a summary of the regulations based on the provided search results:

The EU REACH Regulation, which addresses the safe use of chemicals, was incorporated into UK law on 1 January 2021, known as UK REACH. The restriction on diisocyanates (EU 2020/1149) was also carried into UK legislation, with subsequent modifications made by SI 2021 No. 904 Part 2.

Labelling Requirements: Effective from 24th February 2022, products sold within the UK containing a total monomeric diisocyanate concentration greater than 0.1% and intended for professional or industrial use must have the following statement on the product label: “As of 24th August 2023, adequate training is required before industrial or professional use.”

The Impact of 2023 Isocyanate Regulations on adhesive products

In 2023, the UK will see the implementation of new isocyanate regulations that will significantly influence the adhesive industry, particularly concerning the labelling of adhesive products. Here’s a concise overview of the implications of these regulations on product labelling:

Background:

Isocyanates, commonly found in polyurethane adhesives, are chemicals known for their reactivity. They have been identified as potential respiratory and skin sensitizers, leading to concerns about health risks associated with their exposure.

Labelling Requirements:

Presence Indication: All adhesive products containing diisocyanates will be mandated to have clear labels indicating the presence of these chemicals. This ensures users are informed and can take necessary precautions.

Safety Information: Labels will need to provide safety information, including potential risks associated with exposure and guidance on safe handling, storage, and disposal.

Training Information: Given the requirement for adequate training before using these products, labels might also need to indicate the necessity for such training or provide references to where users can access this training.