Digital embellishments

Home / Full Product Range / Digital Labels / Digital embellishments

DIGITAL EMBELLISHMENTS FAQ’S

Why do my labels need embellishments? In an ever more crowded marketplace, packaging is becoming increasingly vital when it comes to differentiating your brand. Adding an embellishment to your label can add an extra luxury look, marking out your product as a high quality item. Why are embellished labels normally so expensive? Features such as foiling and embossing are typically added offline, that is after the main labels are produced. The labels need to be taken to a second machine and the embellishment added – so in effect you are paying for them to be run twice. Additionally printing plates are required to add the embellishment, sometimes costing several hundreds of pounds. What are the advantages of your digital embellishments? The system we use does not require plates, so immediately you are saving on expensive tooling. The embellishments are also added inline on the same machine, so the production time is much less than the traditional method. This means cost savings for you. What if I have multiple label designs? Many customers come to us with multiple label designs, ideally requiring a feature such as a foil, spot varnished area or embossing. In the past, due to costs, you may have been limited to having the embellished area uniform across the different sorts. Our new digital capabilities mean that you can now have different coloured foils in different designs, or the embossing can be unique to each sort. Are there minimum order quantities? No, we do not have any minimum order quantities. Can I see what the labels are going to look like before I commit to a full production run? Yes, for the first time it is now possible to offer printed samples from your artwork – WITH FOILING, EMBOSSING OR SPOT VARNISHING.Embellishments Labels FAQs

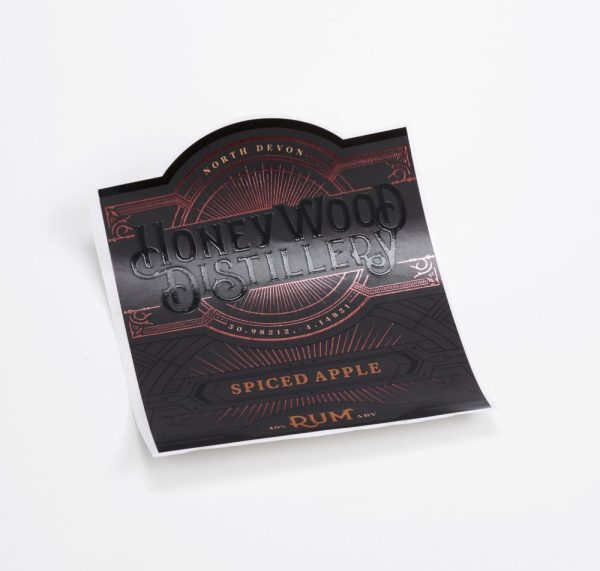

In an ever more crowded marketplace, packaging is becoming increasingly vital when it comes to differentiating your brand. Adding an embellishment to your label can add an extra luxury look, marking out your product as a high quality item.

Features such as foiling and embossing are typically added offline, that is after the main labels are produced. The labels need to be taken to a second machine and the embellishment added – so in effect you are paying for them to be run twice. Additionally printing plates are required to add the embellishment, sometimes costing several hundreds of pounds.

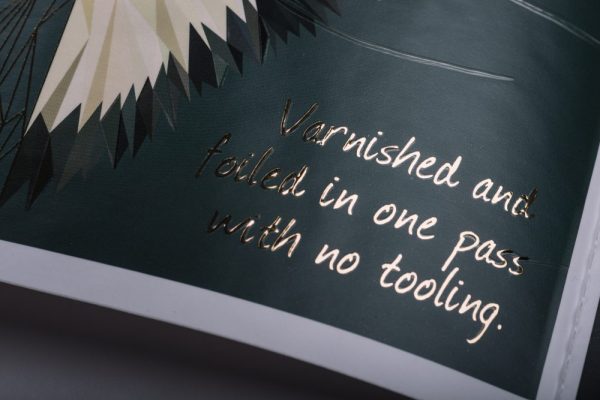

The system we use does not require plates, so immediately you are saving on expensive tooling. The embellishments are also added inline on the same machine, so the production time is much less than the traditional method. This means cost savings for you.

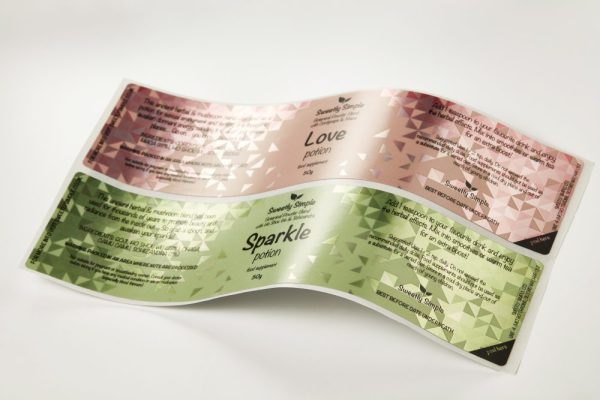

Many customers come to us with multiple label designs, ideally requiring a feature such as a foil, spot varnished area or embossing. In the past, due to costs, you may have been limited to having the embellished area uniform across the different sorts. Our new digital capabilities mean that you can now have different coloured foils in different designs, or the embossing can be unique to each sort.

No, we do not have any minimum order quantities.

Yes, for the first time it is now possible to offer printed samples from your artwork – WITH FOILING, EMBOSSING OR SPOT VARNISHING.

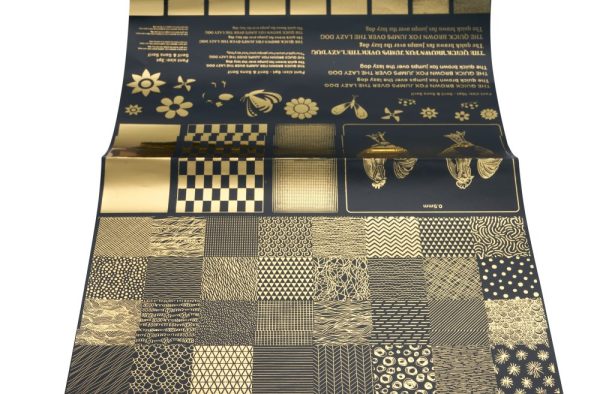

Here are some of the most sought-after embellishments for labels:

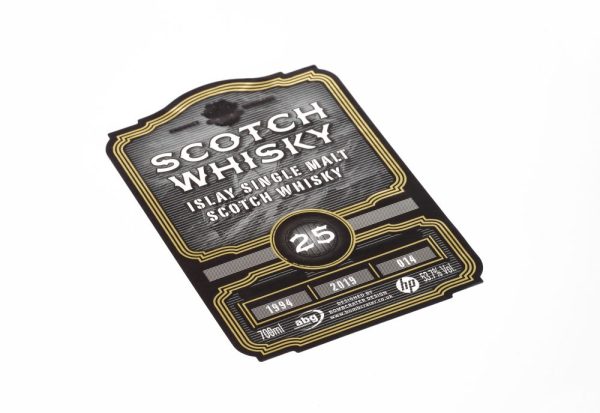

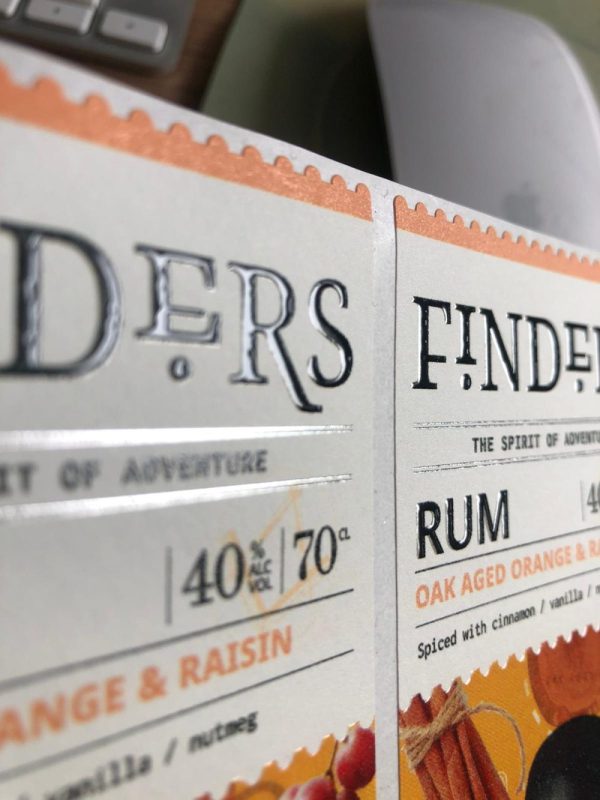

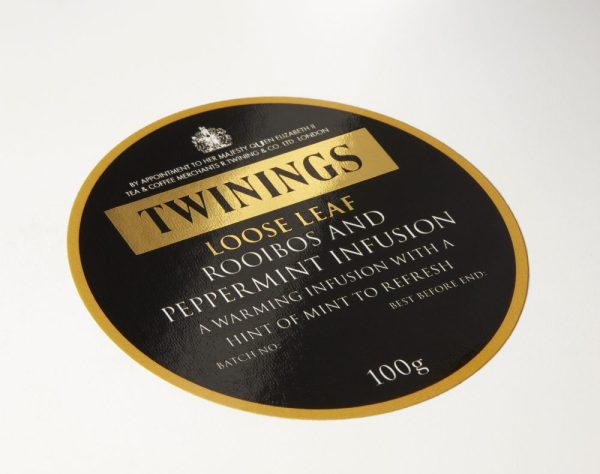

Foiling: This method utilises heat and pressure to affix metallic foil, typically gold or silver, to the label. It imparts a sense of luxury, making it a favourite for high-end products.

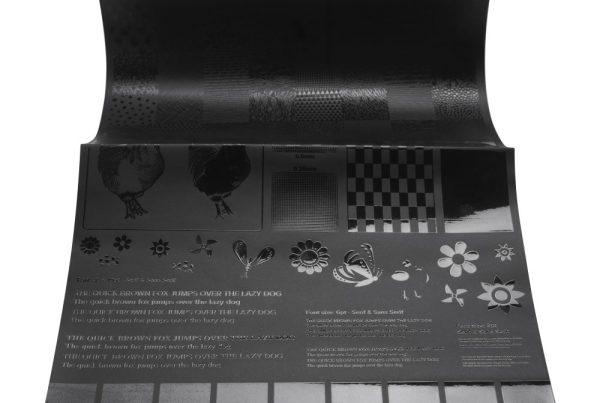

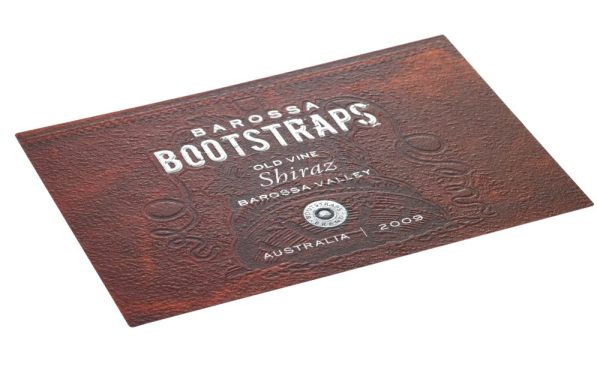

Embossing: Embossing elevates specific sections of the label to produce a three-dimensional effect, while debossing exerts pressure downwards. Both techniques introduce texture and a sense of depth.

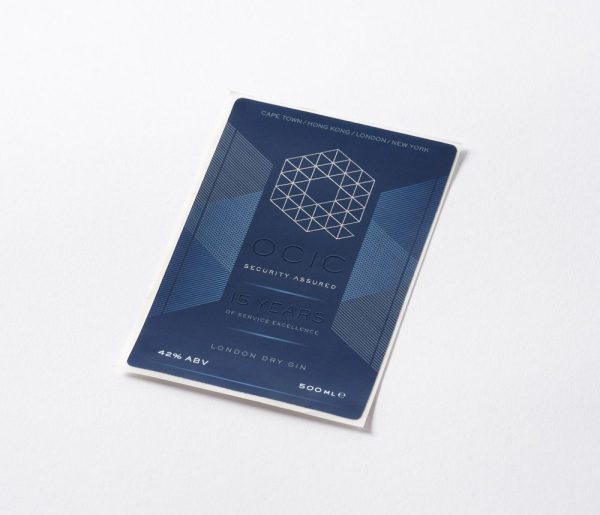

Spot UV: By applying a UV-cured coating to select areas of the label, it bestows a glossy finish. This technique is perfect for accentuating certain elements, such as brand logos or product names.

Lamination: This involves overlaying the label with a slender protective film. Not only does it bolster the label’s durability, but it also offers a polished finish, available in both glossy and matte variants.

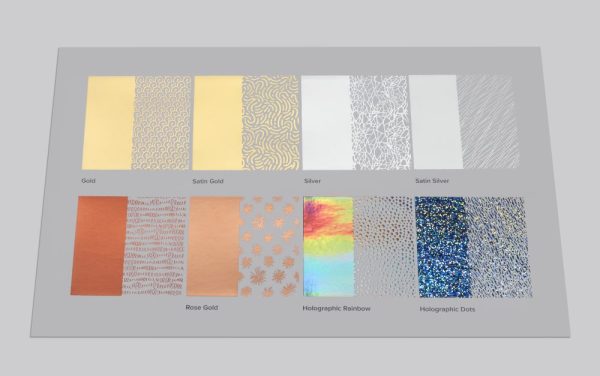

Holographic Effects: These radiant, multi-faceted finishes alter their appearance based on the viewing angle. They serve dual purposes: enhancing visual appeal and acting as a security measure.

Varnishes: These raised coatings, when applied, introduce a tactile dimension to specific sections of the label, enriching the overall sensory experience for the end-user.

Glitter and Metallic Inks: Infused with sparkle and sheen, these inks captivate attention, adding a festive touch to labels.

Embellishing refers to the general act of adding decorative details to enhance an item’s appearance. It’s a broad term encompassing various design techniques. One of those techniques is embossing, which is a specific process that creates a raised design on a surface, giving it a three-dimensional look. In essence, while embellishing is about overall decoration, embossing focuses on texture and relief.

DIGITAL EMBELLISHMENTS FAQ’S

Why do my labels need embellishments? In an ever more crowded marketplace, packaging is becoming increasingly vital when it comes to differentiating your brand. Adding an embellishment to your label can add an extra luxury look, marking out your product as a high quality item. Why are embellished labels normally so expensive? Features such as foiling and embossing are typically added offline, that is after the main labels are produced. The labels need to be taken to a second machine and the embellishment added – so in effect you are paying for them to be run twice. Additionally printing plates are required to add the embellishment, sometimes costing several hundreds of pounds. What are the advantages of your digital embellishments? The system we use does not require plates, so immediately you are saving on expensive tooling. The embellishments are also added inline on the same machine, so the production time is much less than the traditional method. This means cost savings for you. What if I have multiple label designs? Many customers come to us with multiple label designs, ideally requiring a feature such as a foil, spot varnished area or embossing. In the past, due to costs, you may have been limited to having the embellished area uniform across the different sorts. Our new digital capabilities mean that you can now have different coloured foils in different designs, or the embossing can be unique to each sort. Are there minimum order quantities? No, we do not have any minimum order quantities. Can I see what the labels are going to look like before I commit to a full production run? Yes, for the first time it is now possible to offer printed samples from your artwork – WITH FOILING, EMBOSSING OR SPOT VARNISHING.Embellishments Labels FAQs

In an ever more crowded marketplace, packaging is becoming increasingly vital when it comes to differentiating your brand. Adding an embellishment to your label can add an extra luxury look, marking out your product as a high quality item.

Features such as foiling and embossing are typically added offline, that is after the main labels are produced. The labels need to be taken to a second machine and the embellishment added – so in effect you are paying for them to be run twice. Additionally printing plates are required to add the embellishment, sometimes costing several hundreds of pounds.

The system we use does not require plates, so immediately you are saving on expensive tooling. The embellishments are also added inline on the same machine, so the production time is much less than the traditional method. This means cost savings for you.

Many customers come to us with multiple label designs, ideally requiring a feature such as a foil, spot varnished area or embossing. In the past, due to costs, you may have been limited to having the embellished area uniform across the different sorts. Our new digital capabilities mean that you can now have different coloured foils in different designs, or the embossing can be unique to each sort.

No, we do not have any minimum order quantities.

Yes, for the first time it is now possible to offer printed samples from your artwork – WITH FOILING, EMBOSSING OR SPOT VARNISHING.

Here are some of the most sought-after embellishments for labels:

Foiling: This method utilises heat and pressure to affix metallic foil, typically gold or silver, to the label. It imparts a sense of luxury, making it a favourite for high-end products.

Embossing: Embossing elevates specific sections of the label to produce a three-dimensional effect, while debossing exerts pressure downwards. Both techniques introduce texture and a sense of depth.

Spot UV: By applying a UV-cured coating to select areas of the label, it bestows a glossy finish. This technique is perfect for accentuating certain elements, such as brand logos or product names.

Lamination: This involves overlaying the label with a slender protective film. Not only does it bolster the label’s durability, but it also offers a polished finish, available in both glossy and matte variants.

Holographic Effects: These radiant, multi-faceted finishes alter their appearance based on the viewing angle. They serve dual purposes: enhancing visual appeal and acting as a security measure.

Varnishes: These raised coatings, when applied, introduce a tactile dimension to specific sections of the label, enriching the overall sensory experience for the end-user.

Glitter and Metallic Inks: Infused with sparkle and sheen, these inks captivate attention, adding a festive touch to labels.

Embellishing refers to the general act of adding decorative details to enhance an item’s appearance. It’s a broad term encompassing various design techniques. One of those techniques is embossing, which is a specific process that creates a raised design on a surface, giving it a three-dimensional look. In essence, while embellishing is about overall decoration, embossing focuses on texture and relief.